Traditional print on textile : The origin of colored designs and motifs on cloth by basme or mold apparently appeared in India in the 4th century before Christ. It is written in Chinese records that printed fabrics were brought to China from India in 140 BC. In Persian, the word chit means printed fabrics, and this word is originally from India.

The discoveries made in ancient Egyptian monuments show that Chit was imported to the markets there until the 14th century. During the Sasanian period, printing on fabric was found in Iran and new methods were invented in the decoration of silk, cotton and silk fabrics.

Printing is dyeing in parts of the fabric and its difference with dyeing is that in dyeing, all parts of the fabric are the same color, but in printing, you can create a desired design by using one or a number of colors on a white or painted background. In the 7th century AH and at the same time as the invasion of the Mongols, they entered Iran and in the past, Isfahan, Shiraz, Borujard, Hamadan, Rasht, Kashan, Nakhjovan, Yazd, Semnan, Gonabad, Najaf Abad, the villages of Farsan, Ghazbarkhwar, Khorzarq, Barkhar, Lanjan and Sabra was considered one of the important centers of kalamkar and in terms of the importance of the fabrics of Boroujerdi kalamkar, it was in the first rank

video of traditional textile print

textile printing is a living embodiment of the culture and art of this land.

In different periods of history, it is a sign of a deep and powerful culture that not only resisted the invasion of different ethnic groups, but also managed to dissolve foreign imposed cultures and give it an Iranian appearance.

Indeed, what do Iranian people know about art except that they are used to its constant presence by their side and how can people talk about an issue that they are familiar with.

For the research that was given to us, we went to various centers so that we could have a complete knowledge of a part of the art that we may only be familiar with by name, but not a superficial knowledge, because the handicrafts of this region have many variations and subtleties that we In the labyrinth of its subtleties, we seek to find the unknowns of this beautiful art to evoke a corner of ancient Iranian civilization.

textile printing and traditional printing

The production of colored designs and patterns on cloth by basme or mold apparently appeared in India in the fourth century before Christ. It is written in Chinese records that printed fabrics were brought to China from India in 140 BC. In Persian, the word chit means printed fabrics, and this word is originally from India. Strabo, the Roman historian, wrote in the first years after Christ that during his time, printed fabrics were sent from India to Alexandria. The discoveries made in Egyptian ancient works show that Chit was imported to the markets there until the 14th century. During the Sassanid era, fabric printing was found in Iran and new methods were invented to decorate silk, cotton and silk fabrics.

The first printed cloths in Northern Europe from Gursent Cassarius from Arles St. Caesarius Arles (around 543 AD)

Has been achieved. These fabrics were made in the oriental style. Finally, when screen printing became popular in Europe, its method was different from the East.

The chit maker of medieval Europe, from the 13th century onward, transferred the colored substance mixed with a special glue from his molds to the fabric and only printed on it. On the other hand, oriental quilting uses real colors that color all the fibers and fibers of the fabric.

Printing is dyeing in parts of the fabric and its difference with dyeing is that in dyeing, all parts of the fabric are the same color, but in printing, it is possible to create a desired design by using one or a number of colors on a white or painted background from around the beginning of the century In the 7th A.H. and at the time of the invasion of the Mongols, they entered Iran, and in the past, Isfahan, Shiraz, Borujard, Hamadan, Rasht, Kashan, Nakhjovan, Yazd, Semnan, Gonabad, Najafabad, the villages of Farsan, Gazbarkhwar, Khorzarq, Barkhar, Lanjan, Sabrah, etc. .. they were considered among the important centers of penmanship and in terms of the importance of penmanship fabrics, Boroujerdi was ranked first.

penmanship cloth

Kalamkar is a Famous iran handicrafts and is type of fabric printed by wooden molds and borrowed from its initial production method, and it is still flourishing and popular in Isfahan and in a more limited way in Mashhad and Damghan. From the beginning of the 7th century AH and at the time of the invasion of the Mongols, they entered Iran, and in the past, Isfahan, Shiraz, Borujard, Hamedan, Rasht, Kashan, Nakhjavan, Yazd, Semnan, Gonabad, Najafabad, the villages of Farsan, Ghazbarkhwar, Khorzarq, Barkhar, Lanjan. , Sabra and… were among the important centers of calligraphy, and in terms of the importance of calligraphy fabrics, Boroujerdi was ranked first.

Kalamkar is a type of fabric printed by wooden molds and it borrows the form from its initial production method, and it is widely used in Isfahan and in a more limited way in Mashhad and Damghan.

The basic method of penmanship is that from the beginning, they painted the desired designs with a pen on cotton fabrics (and probably silk) and then used special chemicals to fix the colors.

But due to the lack of necessary coordination between the motifs and because this work required a lot of time, the gradual development of pen-making made it possible to use wooden stamps to replace the use of pens in order to access more production and create uniform harmony of motifs. In general, the use of kalamkar fabrics on linen, trousers, canvas and other types of fabrics is also widespread, and in fact, the period from the beginning of the tenth century AH (about 1502 AD) to the middle of the twelfth century AH (around 1722 AD) is the peak of kalamkar making and the day of exalted work. He took into account the art and craft of the pen makers of the country. What is the fact that during the mentioned years, almost the majority of the people of the country were consumers of Qalamkar fabrics and also used this fabric to prepare all kinds of clothes such as tablecloths, covers, rugs, quilt covers, bedspreads, bathroom needles, rugs, back covers, handkerchiefs and notebooks. Some people used it to decorate mourning gatherings, and some of the products are exported abroad.

Today there are three methods that can be used separately and together:

Basmeh stamps the work on the fabric with a mixture of Katira paste or wax. Then he dyes the cloth; Its stamped part remains white and colorless. Then they wash this seal and repeat the same thing with another color, sometimes the colors are partially overlapped, thus creating different patterns. This method is common in Iran and is still used for some designs.

The basme kar applies a dye such as alum, kath or vegetable gum on the fabric. When the fabric is dyed with some materials, the color affects this part of the seal and becomes fixed, and when the fabric is washed, the color of the other parts is washed away and disappears, leaving only this part. This method is the most important method and it is known in Iran even today because of the two colors that remain while printing.

Basmeh stamps the color directly on the fabric (basmeh). Some of the old colors can be used in this way, and some of today’s synthetic colors can also be used directly, and Iranian professionals use these types of colors for two other colors.

Most of the chit makers in Iran hire mold makers or cooperate with mold makers who repair and prepare the mold for each role.

The method used today by most chit makers in Isfahan, Kashan and Yazd is called four-color basme. The map is carefully divided into parts such as the middle part, border, corner, etc., so that the artist can reduce the size of the templates. And because all the parts are in four colors, black and red. It will be colored blue and yellow. Four molds should be made for each part.

In order to prepare the pen, the desired motifs are carved into different colors and a maximum of four colors on wood such as pear wood and hawthorn, and then the desired colors are used by the producer as described in the table below.

To prepare the fabric for dyeing this print, first wash it in running water for a while to remove the food and waste materials in the fabric.

Such a fabric also needs whitening, and for this reason, it is necessary to sprinkle water on it after washing on a wide sandy floor, so that after some time it will turn completely white due to sunlight. Sometimes the pen makers prefer to make the background of the fabric yellow, and for this purpose, they usually dip the washed fabric in special troughs containing a solution of pomegranate peel and water, and in this way, they give it a yellow background color.

In the production stage, the master first paints the mold with black color and places it on the fabric at the desired point, and with a punch, the pattern is transferred from the mold to the fabric. Then the red color is printed in the above-mentioned manner and after the color dries, the fabric is washed to remove the excess colors.

To stabilize the colors of the pen, for every 1000 meters of fabric, 12 kg of grated pomegranate peel and about 90 kg of Runas kernels are poured into the pot that is boiling, and it is stirred until it is completely mixed. Then the dyed and washed fabrics are put into the pot. The heating process continues.

The method of boiling the kalamkar fabrics is that the fabrics are put in piece by piece and it is turned upside down by means of long sticks so that the resulting solution penetrates all the parts of the fabric. After finishing, the fabric is washed again, placed on wide sand, and water is sprinkled on it so that the cream background of the fabric becomes white.

App cheat or penman includes the following steps:

A- The fabric used is hand-woven carpet. If part of the design is colored, as we said before that the background of the pattern should be yellow and not yellow, in that case, the canvas is boiled in a solution of pomegranate peel, then it is drained and dried.

B- The pencil maker puts the dry chit in the form of a ball on his work table, which is a short board. He pulls a piece of chit and spreads it on the board, takes out the first printing mold, and moistens it with iron from a cup that is next to him.

They have added some amount to this tooth so that it does not run while printing. A piece of cloth (shawl) is drawn over the paint cup and its loop is tied with a thread so that the cloth comes in contact with the teeth, and thus the pen maker will always have a certain amount of color. He puts the wet mold on the sheet and presses it with his left hand and uses his right hand as a hammer to hit the mold. Of course, in order not to hurt his hand, he covers his hand with woolen cloth or felt.

This fabric or felt is called term. Once again, he moistens the mold and puts it on the cloth again, making sure that the edge of the mold falls on the mole from the previous time, and continues the same work.

C- After completing the printing of all the black templates, he applies the wet template to the red tooth in the same way as mentioned above and makes sure that the printing is on the previous spots.

D- When all the balls of cotton cloth are dyed red and black, he takes them all to the dyer’s house and immerses them in the boiling solution of Runas. In the first bath, the wet lines become black and the wet lines become red and white alum. In the next washes, the excess bleach solution is removed, the fabric is dried in the sun and sent to the working pen again.

E- The blue mold takes the indigo color from the color container in the same way as mentioned above and uses the third color.

F- The last stage of chit printing is the stamping of yellow color, which is done in the form of blue color, and this is how the penmanship process ends.

G- They take the cloth to the dyer’s house again and boil it in water until its color appears, and when it is spread out in the sun, its color becomes perfect.

Another way to obtain the yellow color of the background, which we mentioned in paragraph A, is as follows: 20 to 30 dyed chit cloths are spread on the ground after being soaked, and each one is placed on top of the other, and each one is slightly They pour soft pomegranate skin around it, then put another one on top of it, then sprinkle some water on it and do not touch it for several hours. After they are drained, they are dried in the sun. This action is very useful for proofing the color. In Isfahan and Kashan-Vizd drawing centers, which produce large quantities of each design at a time, chit makers work in batches, each batch prints one color and gives it to another batch for the next color.

How to print batik: Batik printing:

Batik is a handmade art that is produced in the southeast of India, Europe and part of Africa, and a type of it known as Kalakei is mostly found in the surrounding villages, especially in the rural areas of Esko, Kahnmo, Eskandan, Dizge, and Vail Road.

Batik is Javanese (one of the islands of Indonesia), which in Nafisi culture means fence and zareeh, and the common people call it kalaghi, kalaghi, and klakahi. Because in the distant past, the parts of the fabric that were to be dyed were usually tied or sewn in certain ways and then started dyeing. Naturally, because the color could not penetrate into the knotted or sewn parts, after the dyeing operation was finished and the knots and sewn points were opened, the parts that did not absorb the color would take on a negative state in the colored text, and the market there is usually only one color and more. Black color is used. These random motifs evoke the feeling of crow’s feathers, and for this reason, it is called Kalani to be distinguished from other dyed textiles.

Batik, which is more like light-resistant printed fabrics. It refers to heat, humidity, and other atmospheric factors. It is originally a Chinese art and more than 2000 years have passed. Currently, in addition to Iran, it is popular as a national art in some of the South and East Asian countries, and usually the artisans use very simple and primitive tools. they do. Archaeological findings in the museums of Iran and other countries of the world have identified the production of fabrics with batik print. It goes without saying that it seems certain that fabric decoration by means of batik art has been popular since long ago and even before the discovery of other dyeing methods, and there were people who made stamps and wooden molds with the help of simple tools, clothes and other commonly used fabrics. Planted with different colors.

These printing methods were gradually developed by the primitive peoples of Indonesia and by discovering plants whose extracts prevent the penetration of color into the fabric, a new development in this art and industry emerged. In this way, artisans dissolved banana leaves in a solution of caustic soda, and the sticky liquid that obtained by mixing with soft sand or clay and then using special pens or other tools of this resistant material as ink and painting the desired designs on raw silk, since after dyeing and washing the fabric, the points that were previously The resistant material was coated and remains white. If the artisans wanted to paint the white parts or multi-color the fabric, they would cover the painted parts with a resistant material and paint it again or several times.

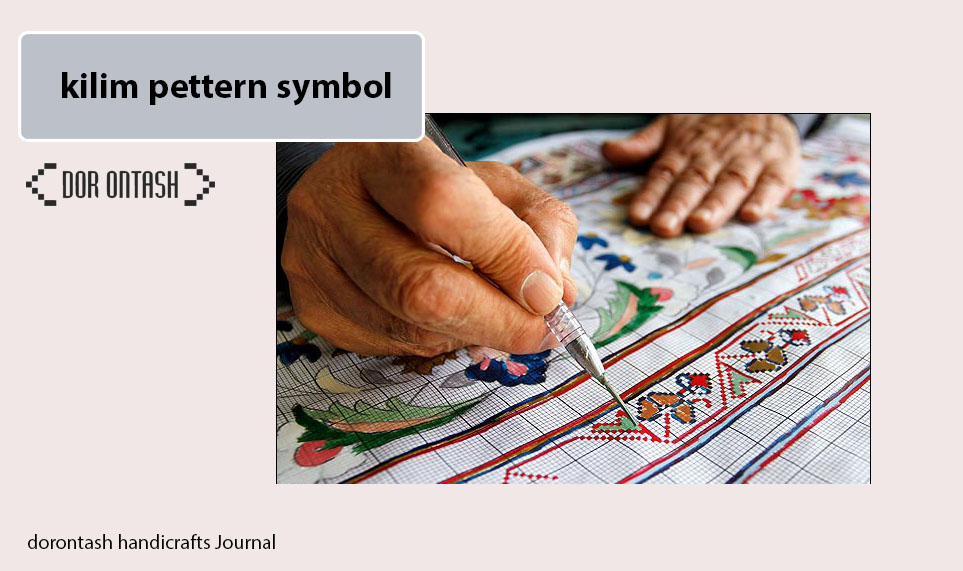

one of the best and popular handicraft in Iran is pesrian kilim bags, which are produced in different cities.

photo of Traditional print on fabric