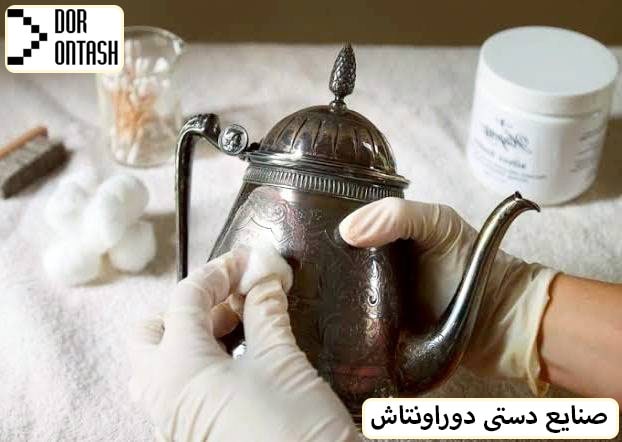

Silversmithing is one of the oldest crafts in Iran, which was also called wiresmithing. The work of silversmiths is to make silver dishes and silver ornaments. Silversmiths perform all the stages of producing silver dishes or silver ornaments in the workshop. The process of making silver jewelry includes different stages in silver making. From silver smelting to rolling, metalworking, soldering, and possibly engraving. Nowadays, due to the mechanization of silver making and specialization of work, silver making is produced in well-equipped factories. Of course, traditional silversmiths no longer perform all silversmithing steps in their workshop. And they must order some of the silver-making processes to other workshops. Silver making is mainly done in the cities of Isfahan, Tabriz, Shiraz and Zanjan.

Silver video

The art of silversmithing

Silversmithing is an art in which processes such as penning, hammering, etc. are performed on silver and all kinds of ornaments and dishes are made with it. This art is widely practiced in provinces such as Qazvin and Isfahan.

After gold and goldsmithing, one of the most valuable and widely used metals is silver, with which, in addition to ornaments, they make dishes and decorative objects.

Silver is a valuable metal like gold and copper that is found in pure form in nature and its extraction is done from ore. There are many mines in Iran where silver ore is found.

One of these mines is the Nakhlek mine in the middle of the Lut desert in the north of Anark, which was used to make cement containers during the Sassanid period. The art of silver making was very prosperous at that time.

At that time, silver work was done in different ways. Among these methods were the metalworking art of casting in cement objects, making silver objects by hammering, making lined dishes. They are poured into a mold called Riche.

Riche is in the form of two iron plates, one of which has two strings around it. These two plates are locked together and molten silver is poured into it from the gap above them. Then it is made into ingots. These ingots are converted into different thicknesses by rolling machines and they are thinned.

The steps of making silver and making silver ornaments

In this article, we are going to explain the making of silver jewelry in 5 steps. But it should be said that making silver jewelry includes more than five stages. These five steps are 1. Sawing, 2. Filing, 3. Metalworking, 4. Soldering and 5. the payment. It should be said that before these five stages, the process of melting silver and turning it into silver ingots, as well as rolling and possibly casting, must have been done.

Silver making and making silver ingots and rolling

It is possible that the makers of silver jewelry can get the silver they need from second-hand or used silver. Therefore, it is necessary to first melt or melt these silvers. The method of melting silver in the article “Do you know how to melt silver coins?” We have explained completely and in detail. The result of the silver melting stage is the creation of silver ingots. Silver bullion is a small plate with a specific thickness.

It should be noted that if you use pure silver to make silver jewelry, you must use silver bar. Adding a load of silver to pure silver is the same as refining silver. In other words, in making silver jewelry, you have to convert pure silver into sterling or argantum alloy. After the silver ingot is obtained, it is time for lighting. In rolling, silver ingots are converted to the required thickness using a roller.

Silver jewelry casting

It has been customary to use sand for casting silver since ancient times. In making silver dishes, they use metal molds such as brass and aluminum molds. After casting, the resulting ornaments may have a few frills. These frills can be removed using a file. In the following, we will explain the five main stages of silvering of silver jewelry:

1. Sawing or sawing

A saw is a tool used to cut silver and make grooves on it. Since silver is a soft metal, it can be cut with thin saws, such as a hacksaw. They use saw number 2, 4 and 6 to cut silver. In general, in jewelry making, the size of the saw is determined by number by number. The higher the saw number, the finer the saw. For example, saw number 6 is finer than saw number 2 and 4. That’s why they use this number for finer cuts.

One of the most important points of silver sawing is to do it correctly and avoid creating questions. Sawaleh is the silver dust that is created by sawing. Usually, it is a very difficult process to collect silver and melt it. Therefore, inaccuracy in sawing and creating more problems will cause loss and waste of silver.

2. filet

Sohan is also called Gora. The fineness of a file, like a saw, is determined by a number. The higher the number of the file, the finer the teeth of the file. For example, file No. 1 has coarse teeth and creates a lot of chips or questions. Therefore, when making silver jewelry, you should use the appropriate file for that part of the jewelry. The file is produced in two semi-circular and flat shapes.

On the other hand, the more accurately sawing is done, the less filing will be needed. The most suitable file for jewelry making is number 2, 4 and 6. It should be said that file No. 2 is a medium file, which is the most suitable file in most cases. When filing, never move the file back and forth. Rather, the movement of the file should be done in one direction and towards the outside of the body.

3. Metalworking is the most important stage of silver making

In making silver jewelry, the metalworking step includes several other microsteps. These micro-steps include hammering, casting, casting and several other sub-steps. We can safely say that hammering is the most important stage of silver metalworking. Of course, maybe when you hear the name of hammer, you will remember hammering on silver metals. But it must be said that there is also a hammering stage in making silver jewelry. However, with the difference that the hammer used in making jewelry is very delicate and made of plastic.

Silver hammering is usually done using a series of prepared anvils. The shape of these anvils is very diverse and they are used to shape ornaments. For jewelry hammering, first, the parts that need to be bent are placed on the corresponding anvil. And then they give it very controlled blows using a plastic hammer. Hammering silver jewelry requires a very high skill. Therefore, the masters of silversmithing advise the students of silversmithing to fully practice the hammering stage on metals such as copper.

4. Silversmithing and soldering

They must be familiar with soldering. Maybe most people have a soldering iron in their homes. Soldering silver jewelry is exactly like soldering electrical wires. Of course, a few points should be noted. First, soldering in silver making is done in two types: hard soldering and soft soldering. Suppose you have two pieces of silver that you want to join together. And suppose that we have done sawing and filing to make these two pieces. And at the end, you have polished these two pieces and made them almost to the final shape. Therefore, the main point is that these two pieces must remain intact and no traces of soldering heat remain on them.

The difference between hard and soft soldering is precisely in observing this issue. If you use soft soldering, the tips of both parts that are under the influence of the soldering machine will melt (reach the melting temperature of silver) and weld together. But in hard soldering, the tips of both parts remain intact and are only connected to the soldering iron. Therefore, the use of hard soldering or soft soldering depends on the type of parts and the diagnosis of the silversmith. Usually, they use a gas soldering machine (gas torch) for soft soldering and an electric soldering machine for hard soldering.

5. Payment of silver jewelry

Polishing is the last stage of making silver jewelry. At this stage, you may have to use a file. Because it is possible that due to soldering, there are some details left at the connection of the parts. And you have to use a file. Of course, at this stage, you should use very fine files with a high number. To polish and polish the surface of silver jewelry, they use a device called polishing wheel (with one-way and two-way dynamo). This device makes the silver surface as clear and shiny as possible.

You should note that the rotation rate of the polishing machine should be proportional to the elegance of the silver jewelry. More rotation of the polishing wheel may scratch the surface of the silver jewelry.